Laser Cutting

- Precise, High Quality Cut Edges

- Production-Grade Repeatability

- Eliminates Need for Additional Finishing

Get a Quote

Or Any of Our 25+ Manufacturing Processes

When Precision Matters,

Laser Cutting is the Solution

Fine Details and Tighter Tolerances with Fast Production Timelines

If you’re looking for an affordable production technology that’s a cut above other options, then you really ought to consider laser cutting. It’s ideal for creating complex parts with fine details that are impossible to achieve using a punch press without the cost of tooling. It can also hold tighter tolerances than industrial water jet cutting.

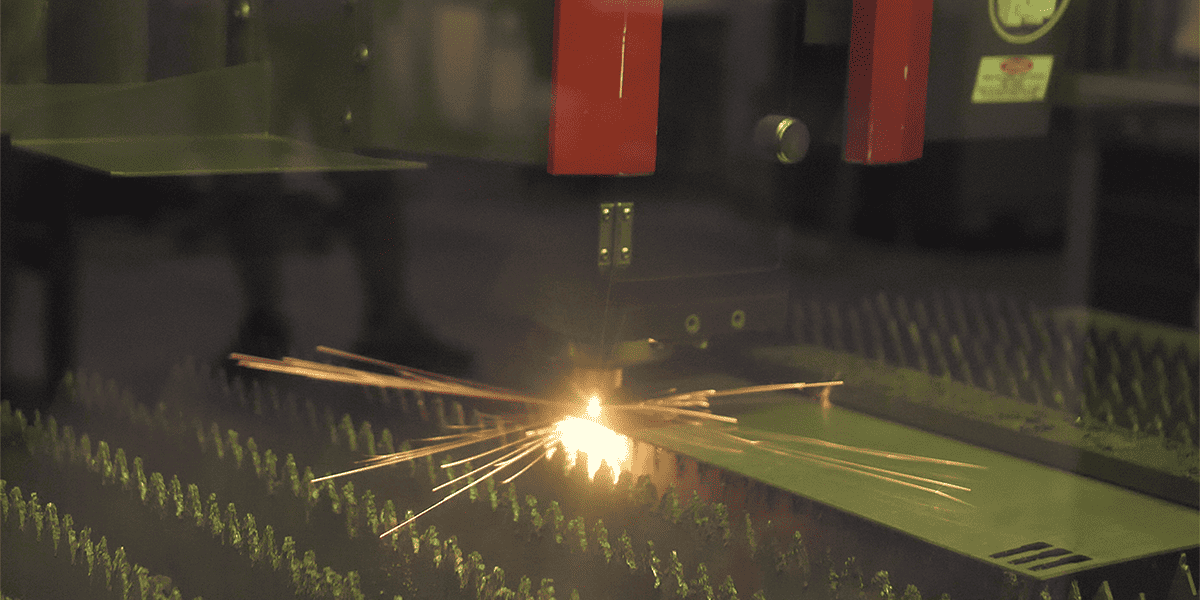

Stand-alone laser cutters can be used to produce prototype parts in as little as two weeks. When paired with automated loading and unloading systems like those used by our Fathom Denver operation, laser cutters are a perfect fit for medium- to high-production applications, too.

Laser Cutting // Get A Quote

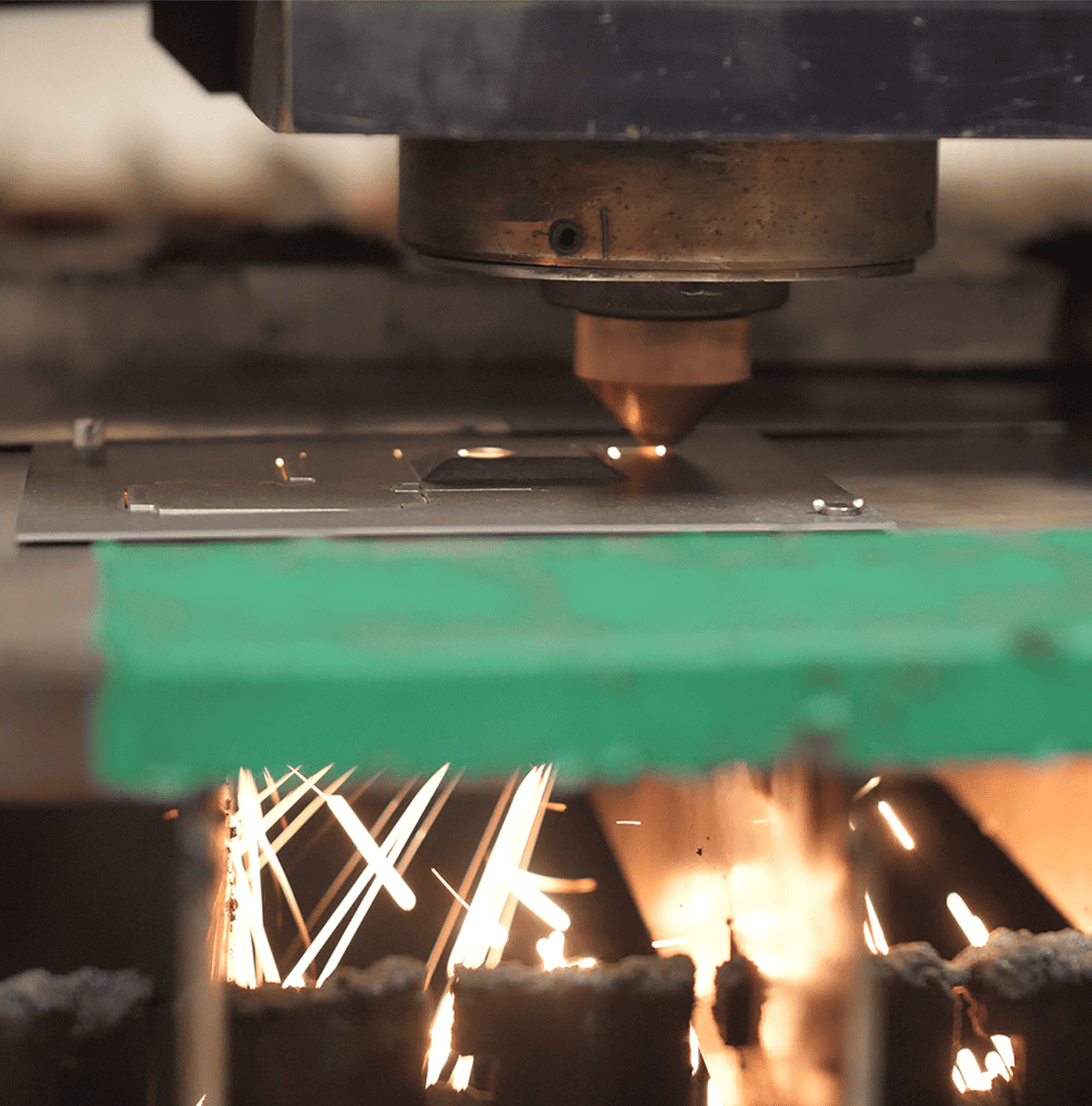

How Does Laser Cutting Work?

Laser cutting utilizes a CNC-controlled, high-powered laser beam to cut, engrave or mark material. Because the kerf width is barely larger than the laser beam, it can be used to cut very fine geometries and complex shapes. The cut is so clean that little or no post-processing is required. Laser cutting can be used to cut a wide range of materials.

There are two main types of laser-cutting technology:

- CO2 lasers use energized carbon dioxide gas to generate an intense beam of light to cut material.

- Fiber optic lasers, a newer technology, use laser diodes transmitted through optical fibers to generate a high-energy light beam that is focused with lenses to create the desired cuts.

In addition to cutting, sheet metal can be etched to incorporate features such as part numbers or serial numbers.

What Materials Can be Processed Using Laser Cutting?

Laser cutting can be used to cut a variety of sheet metal, including aluminum, carbon steel, stainless steel and copper.

Advantages of Laser Cutting

Tight Tolerances // CNC controls maintain critical tolerances while accommodating fine features and larger blank sizes.

No Finishing Required // Laser cutting produces intricate and complex parts with high-quality edge finishes that require little or no post-processing.

Precision Details // Laser cutting can produce small, precise holes.

Maximize Material Use // Multiple parts can be cut from the same sheet, minimizing waste.

Affordability // High speed and high quality make it very cost-competitive and a real value for our customers. That makes it an ideal process for prototype to low-volume production quantities.

Laser Cutting Specifications

Fiber Optic Laser

- Blinding max cutting speed of >1,800 inches per minute

- 0.008 Kerf

- Thickness capacity

- Aluminum: 0.020″ – 0.500″

- Stainless Steel 0.024″ – 0.500″

- CRS 0.024″ – 0.750″

- Copper 0.020″ – 0.125″

Fiber Optic and CO2 Lasers

- Feature size tolerance +/- 0.002″

- Linear and position tolerance +/- 0.005″

- 5′ x 10′ sheet processing size

How Does Laser Cutting Compare to Other Cutting Methods?

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | |

|---|---|---|---|---|---|---|---|

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| * CHEMICAL ETCHING | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

Why Choose Fathom’s Laser Cutting?

Accelerate Your Project with Laser Cutting by Fathom

From one part to thousands, we can help you cost-effectively accelerate your sheet metal projects using laser cutting. Fathom’s team has decades of experience with this technology and can provide you with a range of solutions for your manufacturing needs. Talk to us today about your laser cutting project and how your project can take advantage of its high quality and accuracy.